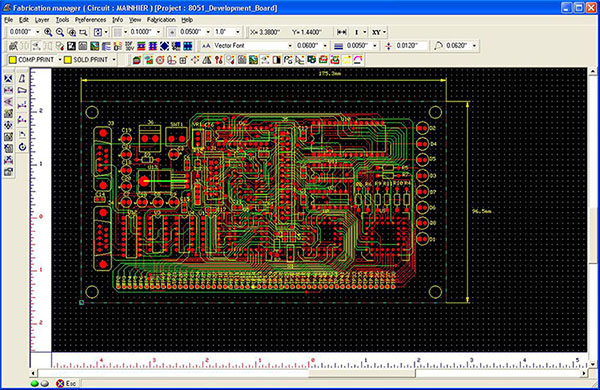

FABRICATION MANAGER

All CAM functions are grouped in this module. Design of PCB layout is completed by individually editing artworks of each layer. User has the option to add targets, coupons, thieving and venting areas. Copper pour areas are checked for possible shortcuts or areas isolated by air-gaps. Final artworks are prepared for photoplotting. The standards

(RS-274D) and extended (RS-274X) Gerber ASCII formats are supported by the program. Powerful

Gerber ASCII file viewer is an integral part of this module enabling to verify artworks before sending them for plotting and manufacturing.

NC Drill data are generated in Excellon format with or without tool movement optimization. Drill templates are created optionally and may be printed or save as Gerber files for photoplotting. This module includes functions for inserting dimensions generation of various mechanical drawings.

PCB Assembly output is generated in IPC-355 and Bare Board Testing output in

IPC-356A formats. The whole project database may be also exported in GenCAM format.

It is recommended that the user go through fabrication tasks before starting Fabrication Manager as it explains in detail all the operations carried out in this module.

Fabrication manager

Board manufacturing data output

Gerber data (274X / 274D) · drill data and External data such as select outputs, and outputs the substrate manufacturing data.

With only click of dimension position, it creates and dimensions automatic reading of dimension lines, you can output and printing of the board Dimensions.

Layout and dimensions shown in addition that can be output to a printer that is connected to the personal computer, you can also output as a DXF file.

Gerber Viewer

It can display to confirm the data of Gerber data, drill data · DXF · HPGL format.

In individual players and superposition, check output is also available.

How to Create Copper Pour Areas?

How to Create Copper Pour Areas?

How to Generate PCB Assembly Outputs?

How to Generate PCB Assembly Outputs?

How to Generate NC Drill?

How to Generate NC Drill?

How to Generate Gerber Output?

How to Generate Gerber Output?

How to Generate Bare Board Testing?

How to Generate Bare Board Testing?

The three main out puts of Fabrication manager are Gerber, NC Drill,

PCB Assembly

Outputs and Bare Board Test Data required for photoplotting. Gerber is the

accepted standard format used as input to photoplotters that generate the design

data on films. These films are used as masters for manufacturing the PCB, the

physical realization of the schematic data. The Gerber Output of the layout

design is converted to an Artwork File to view in EDWin.

The Major Tasks done with Fabrication Manager is as follows:

Optional creation of Copper Planes and Copper Pour Areas

Optional creation of Copper Planes and Copper Pour Areas

Adding Dimensions and Notes

Adding Dimensions and Notes

Printing Layout Documentation drawings

Printing Layout Documentation drawings

Extracting NC-drill data to disk files or paper tape

Extracting NC-drill data to disk files or paper tape

Editing, Dimensioning and Printing of drill templates

Editing, Dimensioning and Printing of drill templates

Editing and Printing of layer artworks

Editing and Printing of layer artworks

Generation of artwork data files in Gerber ASCII format

Generation of artwork data files in Gerber ASCII format

Preview of artworks in Gerber ASCII files

Preview of artworks in Gerber ASCII files

Generation of disk files containing generic data for Pick & Place machines

Generation of disk files containing generic data for Pick & Place machines

Generation of disk files containing bill of Materials

Generation of disk files containing bill of Materials

**ODB++?